Weld-Path2

Overview

A. The need for optimal welding

Welding The challenge of robot welding is to prevent welding defects (welding cracks, etc.). WeldPath-2 aims to achieve welding with few defects by observing the molten pool with a lightweight camera and optimizing the velocity and current values. The optimization of the molten pool is based on the circular shape of the heat-affected zone of the molten pool. This is supported by experiments.

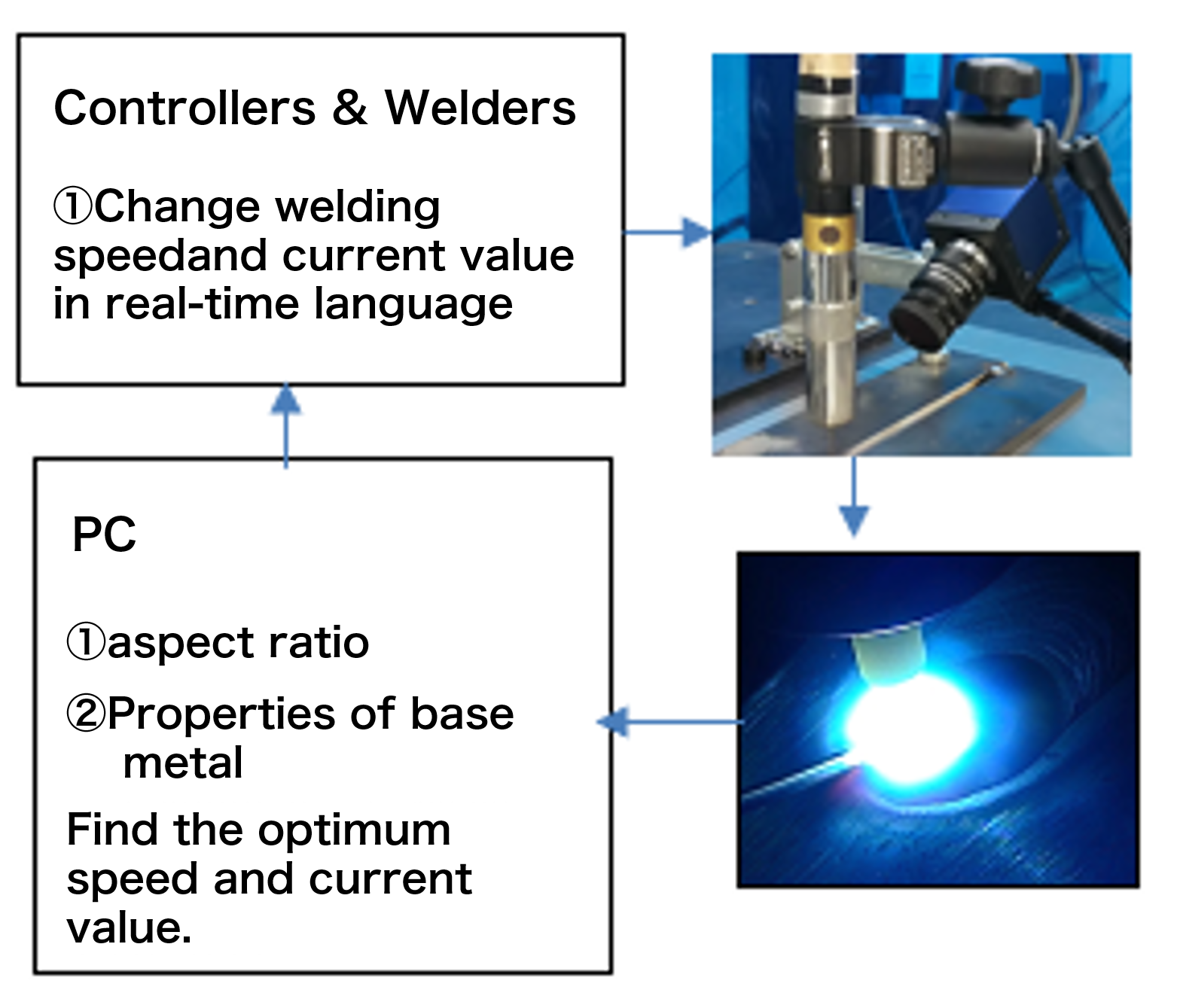

B. Welding condition optimization procedure- Welding molten pool (heat boundary) photographed with a small and lightweight camera (about 300g)

- Optimize welding conditions (welding speed, current value, etc.)

- Change welding conditions in real time through a robot controller

In this system, we conducted a robot welding experiment (TIG welding: base metal SS400) to find the optimum welding conditions. The welding type is bead-on plate. The result is roughly as follows. (Cross section (macro) photo, right in the figure below)

- Optimal welding is achieved when the current value is 200 A and the speed is 150 mm / min. It is a deep penetration and there are no weld cracks (sufficient coupling).

- When the current value is high (300A, 100mm / min) and the speed is slow, the penetration collapses. Welding cracks are occurring.

- When the current value is high and the speed is optimal (300A, 150mm / min), the penetration size is good, but the penetration depth is shallow. Welding cracks are occurring.

Please refer to the figure below. The analysis graph at the bottom left of the screen is plotted with the current value and the changed value, with the aspect ratio on the horizontal axis and the current value / welding speed on the vertical axis. Actually, it is made into a three-dimensional graph and analyzed by taking the axis of velocity or current value in the depth, but it is a pseudo two-dimensional graph. Determine the current value or speed so that the aspect ratio approaches 1.

Optimal welding process

Macro photograph under various welding conditions

Welding

Video of the molten pond

Catalog download

WeldPath Catalog Download is here.